Powder Coating and Fluorocarbon/ Polyvinylidene Fluoride (PVDF)

Our fully-automated vertical powder coating line comes equipped with advanced spray booth and guns from Wagner, Germany. Together with our horizontal powder coating lines, they can deliver a total annual capacity of 24,000 metric tonnes.

The ALBECoat fully integrated powder-coating process offers additional surface finishing that meets the ever-growing demands of our customers and which adheres to the RAL International Colour Code Standard. This single application coating provides a wide-range of solid and metallic colours with different gloss levels and options for texture finish.

In addition, the ALBECoat Fluorocarbon/ Polyvinylidene Fluoride (PVDF) finishing is another high-quality process which involves thinly applying wet-paint to workpieces via electrostatic spray to form a film, which is further heated to polymerize and cure the coating. Fluorocarbon/ Polyvinylidene Fluoride (PVDF) uses a 4-coat system provides excellent colour consistency against fading and UV rays.

Technical Data:

| Powder Coating Properties |

|---|

| Film Thickness (ISO 2360) – average above 60 micron |

| Gloss (ISO 2813, 60 degrees) – 20-40%, 50-95% |

| Impact Resistant (D2794-5/8” ballat 40ib.in) – direct and reverse (both no cracking) |

| Conical Mandrel (ISO 6860) – no cracking at 5mm diameter |

| Adhesion (ISO 2409) – GT = 0 |

| Salt Spray Resistance |

|---|

| ASTM B 117-73 on chromated Aluminium, 2000 hrs (no blistering or loss of adhesion) |

| Humidity Resistance |

|---|

| ASTM D2247 on chromated Aluminium, 1000 hrs (no blistering or loss of adhesion) |

| Accelerated Weathering |

|---|

| DIN 53231 1000 hrs Suntest (150 kilolux, 40 degree C, UV limit 320 nm, water immersion every 20 mins) – total colour change (washed) Delta E = 0.8 – 3.0, excellent gloss retention, negligible chalking |

| Natural Weathering – Florida Exposure |

|---|

| 24 months exposure – excellent gloss retention. Neglible chalking |

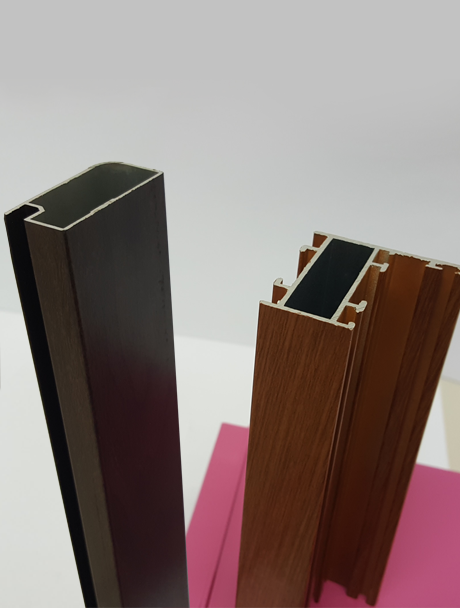

ALWood is a revolutionary new design in wood patterns for aluminum surfaces which adds a natural rich touch of fantasy and elegance to your surroundings. Pro-environment, multi-coloured and refined, ALWood is a work of art accomplished through further heat transfer lamination process on the powder coated finish. ALWood is multi-dimensional and specially designed for both indoors and outdoors.

Tests and requirements for wood grain finishing products:

| Test Item | Test method |

|---|---|

|

Accelerated weathering test, 1000 hours |

EN ISO 11341 |

|

Thickness measurement |

ISO 2808 |

|

Acetic acid salt spray test, 1000 hours |

ISO 9227 |

|

Kesternich moist sulphur dioxide test, 24 cycles |

ISO 3231 |

|

Pressure cooker test (resistance to boiling water) |

BS EN 12206-1 |

|

Pencil hardness |

ASTM D3363 |

|

Abrasion test by falling sand |

ASTM D968 |

|

Impact test |

ASTM D2794 |

|

Adhesion test (cross-cut test) |

ISO 2409 |

|

Cylindrical mandrel bend test, 5mm |

ISO 1519 |

|

Solvent test for polymerization (MEK resistance test, 30 double rub) |

ASTM D5402 |

|

Natural outdoor exposure test, 1 year |

ISO 2810 |